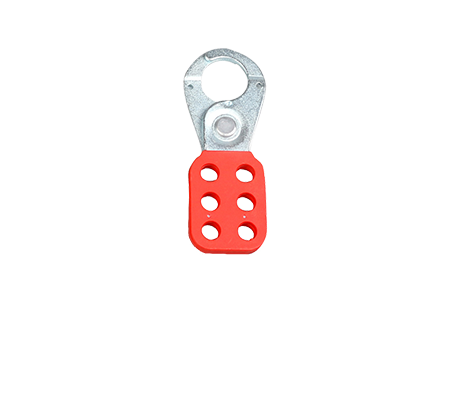

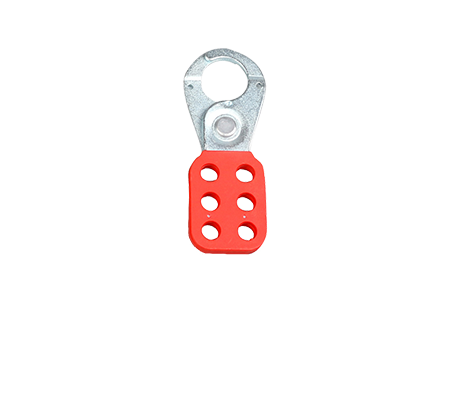

What is a Hasp lockout?

A lockout hasp is a device used in safety procedures, particularly in industrial or maintenance environments, to ensure that dangerous machines are properly shut off and cannot be started up again prior to the completion of maintenance or servicing work. This device is part of a larger safety system known as Lockout/Tagout (LOTO) procedures. The primary goal of these procedures is to protect employees from the unexpected energization or startup of machinery and equipment, or the release of hazardous energy during service or maintenance activities.

What are the application scenarios of Hasp Lockout?

Hasp Lockout is a safety tool primarily used to ensure that equipment, machinery, or power sources are in a safe locked state during maintenance or repair, preventing accidental start-up or energy release, thereby protecting the safety of maintenance personnel and operators. Hasp Lockout has a wide range of application scenarios, and the following are some typical use cases:

- Electrical safety: When maintaining or repairing electrical equipment, using Hasp Lockout can ensure that the power switch is turned off and locked, preventing electrical accidents caused by human error during maintenance.

- Mechanical maintenance: During the maintenance process of mechanical equipment, Hasp Lockout can be used to lock control buttons, valves, or other mechanical components, ensuring that they are not started or moved during maintenance.

- Chemical industry: In chemical processing and storage areas, Hasp Lockout can lock valves and switches to prevent chemical leakage or unsafe chemical reactions from occurring.

- Energy facilities: In energy related facilities such as power plants, gas pipelines, and water treatment plants, Hasp Lockout is used to ensure the safe locking of critical control points during maintenance or repair to prevent accidental energy release.

- Food and Beverage Industry: In food processing and production lines, Hasp Lockout can lock mechanical equipment and production lines to ensure that the production line stops operating during maintenance, avoiding accidental injury and product contamination.

- Transportation industry: When repairing transportation vehicles or facilities, such as ground handling equipment on railways, subways, and airports, using Hasp Lockout can prevent accidental equipment start-up and ensure the safety of maintenance work.

- Architecture and Construction: At the construction site, Hasp Lockout is used to lock construction equipment and electrical systems to prevent accidents during construction or maintenance.

- Education and Laboratory: In schools and research laboratories, Hasp Lockout can be used to lock experimental equipment and chemical cabinets to protect the safety of students and researchers.

- Through these application scenarios, it can be seen that Hasp Lockout is a very important safety measure that helps businesses and organizations prevent workplace accidents, protect employee life safety, and meet the requirements of occupational health and safety management.