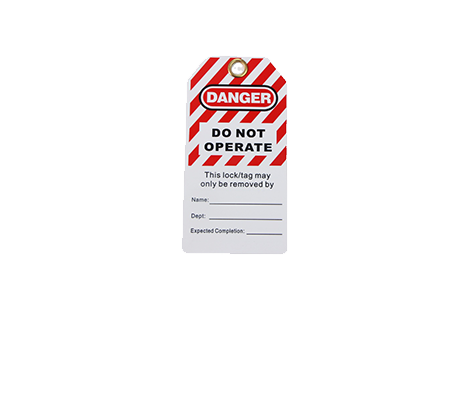

Lockout tags are safety labels that are attached to an energy-isolating device, such as a lockout device on a valve or breaker, during maintenance or repair work. These tags serve as a warning not to operate the equipment or machinery while the tags are in place.

Lockout tags are used in a variety of scenarios to enhance safety by preventing the unintended activation of equipment or machinery. Here are some key application scenarios:

Maintenance and Repairs: The most common scenario for using lockout tags is during maintenance or repairs. Machines are turned off and tagged to alert others that the equipment is undergoing servicing, ensuring no one attempts to use it.

Equipment Inspections: During routine or unscheduled inspections, lockout tags are used to ensure machinery remains deactivated until the inspection is complete and the equipment is deemed safe.

Energy Control: In situations involving control of hazardous energy, such as electrical, mechanical, hydraulic, pneumatic, chemical, thermal, or other energy sources, lockout tags are applied to energy-isolating devices to ensure that the equipment remains isolated from its energy source.

Multi-Worker Operations: For tasks requiring the involvement of multiple workers, lockout tags can be used in conjunction with group lockout devices. This ensures the equipment stays inactive until every worker has removed their personal safety lock and tag from the group lockout device.

Emergency Shutdowns: In emergency situations where equipment must be quickly shut down, lockout tags are applied after the shutdown to prevent reactivation of the equipment until it is safe to resume operation.

Training and Demonstrations: Lockout tags are used during training sessions and demonstrations to educate workers about safety procedures and the importance of lockout/tagout protocols.

Commissioning and Decommissioning: When machinery is being commissioned or decommissioned, lockout tags are used to signify that the equipment should not be operated until it is fully installed and tested or safely shut down and disconnected.

Construction Sites: On construction sites, where temporary setups and a variety of equipment are common, lockout tags help manage the safe use of machinery and protect workers from accidental energization.

Lockout tags play a crucial role in workplace safety across various industries, including manufacturing, construction, utilities, and maintenance services. Their use is an integral part of the lockout/tagout (LOTO) procedures that protect employees from hazards associated with unexpected energization or start-up of machines and equipment, as well as the release of hazardous energy during service or maintenance activities.

GET A QUOTE